In March this year, Rubis Asphalt South Africa (RASA) began its partnership with FFS Refiners through the leasing of 4800m3 bitumen storage tanks at the FFS site in the port of Cape Town. This development has been key to the supply of hot bitumen into the Western Cape region.

On the back of this successful venture, RASA is very proud to announce that we will again partner with FFS, via their Tank Terminal Division, for the construction and leasing for 7500m3 bitumen storage tanks to be built at Maydon Wharf, in the Port of Durban. FFS will invest R350M into the expansion of existing storage at Maydon Wharf. RASA will be the anchor tenant for the first phase of this development. Construction has begun and the terminal is expected to be completed during Q4 in 2023.

The long-term lease agreement between FFS and RASA will incorporate the Durban and Cape Town facilities and further demonstrates Rubis Asphalt commitment to the South African asphalt and road construction industry. It will give the industry reassurance that good quality, hot bitumen will be available throughout the year in Durban. This partnership will also create additional jobs and much needed investment into the Durban and greater KZN economy.

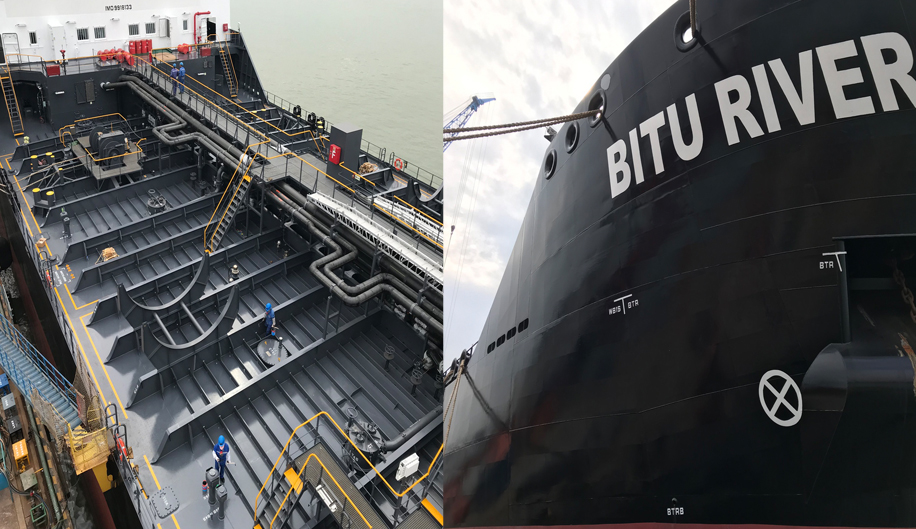

The Bitu River has just left China Merchants JingLing Shipyard. This bitumen tanker equipped with the new generation of Schottel diesel-electric azimuth propulsion system is 145.80 meters long and can transport 16,542 MT of liquid bitumen heated to 150-160 degrees Celsius in 12 independent tanks.

The crew consists of 14 people, including officers and staff responsible for the daily maintenance of the vessel.

With the big support of Maritec Tanker Management, Rubis Group were able to monitor this construction project in all its phases: acquisition process, innovative design and construction to meet our specific needs.

The needs of the African continent in terms of infrastructure are growing. The acquisition of this vessel, equipped with the latest generation equipment, aims to secure the supply of our subsidiaries in Africa.

Rubis Asphalt Middle East is therefore celebrating the arrival of this new bitumen vessel to complete its fleet and support its growth and development.

The Freeport of Monrovia is now a hub for the bulk distribution of bitumen in the Mano River Union (MRU) region, thanks to a partnership initiative between port operators, APM Terminals Liberia and ERES Liberia, a bitumen processing company.

This means that bitumen, the all-important black viscous mixture used in road construction, will now be readily accessible to the Liberian construction industry. The establishment of the hub at the Freeport of Monrovia, a location central to the MRU Region, is strategic for facilitating access to this important commodity needed to transform Liberia’s road network infrastructure and that of the entire region, according to the two companies.

At a brief ceremony attended by stakeholders of the port and roads sector in Liberia to officially launch the hub, the Deputy Minister of Public Works, Mr. Joseph Todd, underscored the essence of such partnerships to the road infrastructure in Liberia.

“The evidence shows that we are faced with a daunting road network infrastructure problem as a country. Several kilometers of our roads are yet to be tarred. This bitumen hub, which will give us ready access to this commodity, is therefore a new dawn for the road sector in Liberia. The government of His Excellency George Manneh Weah is in full support of initiatives like this as it seeks to contribute to accelerating the provision of good roads for the economic growth of Liberia,” Mr. Todd remarked in a keynote address.

The main bitumen manufacturing company, ERES Liberia Inc. is a subsidiary of RUBIS ASPHALT and started operations in Monrovia only last year.

Operations Manager of ERES Liberia, Mr. Winston Faulkner, explained that the presence of the company in Liberia is part of a much larger global operations program which has identified the Freeport of Monrovia as a strategic location for their operations and hence the partnership with APM Terminals Liberia.

“We are excited to partner with APM Terminals Liberia to bring this hub to the Freeport of Monrovia. APM Terminals already had in place the infrastructure needed to store and manage bitumen and this was critical to our decision to partner with them. We expect this project to have great impact not only on the road construction sector of Liberia but also the sub region and we will continue to work together with all stakeholders for the realization of this objective,” Mr. Faulkner said.

With this bitumen hub launch, APM Terminals Liberia has added the handling, management and storage of bitumen to its operational portfolio, demonstrating the expertise and hard work of its fully Liberian Operations team.

Managing Director of the company, Mr. Jonathan Graham explained the rationale behind the partnership and praised stakeholders, especially the company’s operation team for challenging themselves to make the handling of bitumen at the Freeport of Monrovia a possibility.

“What we are launching today is in line with the general goal of making the Freeport of Monrovia, which is the heartbeat of the economy of Liberia, a strategic driver of economic growth. We are excited to add to this portfolio and let me especially congratulate and thank our hardworking operations team who have been fantastic in making sure that we are able to handle bitumen here at the Freeport of Monrovia. We have received crucial support from all our stakeholders, the NPA, LRA, the Ministry of Commerce and many others on this and other initiatives. From an APM Terminals Liberia perspective, these are exactly the kinds of strong partnerships that drives growth.” Mr. Graham commented.

On her part, Honorable Minister of Commerce Mawine Diggs, in a brief remark, said the initiative has the potential of creating jobs and expanding trade within Liberia, which is a key focus of the Pro-poor agenda of President Weah’s administration.

Additionally, the project opens up the Freeport of Monrovia as a key player in the Road construction sector in the Mano River Union. By exporting bitumen for the construction of roads in the three other countries in the sub-region, the Freeport of Monrovia becomes a major contributor to the Mano River Union Road Development and Transport Facilitation Programme which is focused on developing the Loguatuo-Sanniquellie road corridor, linking the north-eastern part of Liberia with Côte d’Ivoire. This corridor has long served as the main hub for trade within the Mano River Union region.

Already, the Lofa road project, the Ganta-Sanniquellie road project and the Freetown airport runway expansion project are utilizing bitumen from this hub.

Other key stakeholders in attendance at the launch event included representatives from the National Port Authority, the National Road Fund, the National Transit Authority, the Liberian Chamber of Commerce and the Custom Brokers Association.

In order to maintain our leadership position in the industry, Ringardas has taken a step further to construct a new tank at the Port Harcourt terminal towards the end of the year 2020. All necessary approval was secured from the authorities concerned to enable us to increase our capacity by 6000MT.

As a company that does not compromise on its integrity, nor the quality of work carried out at its facility to ensure the safety of lives and properties, Ringardas Nigeria awarded the contract to reputable companies to handle different aspects of the tank construction according to their specialization.

Shams Geotek Nigeria Limited, a Nigerian-based company that specializes in designs, was tasked with the substructural design of the tank having 26 piles of 900mm diameter and 22,000mm height. All 26 piles were successfully driven beneath the soil.

ECCR, (Etudes Calculs Conceptions Realisations) a French Engineering company that is globally recognized in tank construction did the superstructural design and supplied all shell and roof steel materials of the tank, while IPI (Iron Products Industries Limited) commenced the mechanical construction of the tank in December 2021.

With the completion of the tank project in September 2022, RNL storage capacity at our Port Harcourt terminal has increased from 9,000MT to 15,000MT (+66%), while the Company’s global bitumen storage increased from 47,000MT to 53,000MT (+12%).

To continue our growth strategy in Africa, Rubis Asphalt acquired a new bitumen tanker, named Asphalt Seminole.

This vessel has been acquired from a Vitol affiliate on 29 April 2022.

Its bitumen loading capacity is 7005 MT, and also equipped with independent bitumen tanks.

The vessel has CAP1 certificate which is the maximum rating related to the condition of hull and machinery according to the Condition Assessment Program.

The vessel is powered by a Wartsila 4 strokes diesel engine developing 4000kW, and also equipped with two diesel alternator and a shaft generator.

Asphalt Teranga will be supplying our affiliates in West and Central Africa.

We decided to rename the vessel to Asphalt Teranga, which means hospitality in Wolof. This is also a wink to the Lions of Teranga, the Senegalese football team who won its first African Cup of Nations this year.

We are currently changing her flag to Panama and the class to RINA, and thereafter Teranga will sail from Istanbul to load the first cargo in Turkey destined to West Africa.

We wish Asphalt Teranga a long life with Rubis Asphalt and a busy schedule to serve our customers for the years to come!

4 March 2022 will be remembered as a special day in the Rubis Asphalt South Africa calendar. Our vessel Viveka arrived at the Cape Town Harbour with approx. 4800MT grade of bitumen 50/70. This delivery is important to us, because it is the first import of bitumen into land-based tanks in Cape Town.

Rubis Asphalt South Africa have entered into a lease agreement with FFS Refiners for the rental of 2 bulk storage tanks at their storage facility at the Eastern Mole in the Cape Town harbour. These 2 tanks, each approx. 2400MT, were originally designed for the storage of bitumen but were eventually converted to fuel oil. Through our impulsion, FFS decided to convert the tanks back into bitumen storage and following a tender process, we were named as the successful bidder.

We have a dedicated loading bay for bitumen, so we are able to offer our customers in the Western, Southern and even Eastern Cape town, hot bitumen “upon request”.

The facility is available 6 days a week and we have seen positive growth in volumes as a result. Our view for this lease agreement is as a necessary step in ensuring that our customers have peace of mind regarding availability of bitumen in the region.

Given the change in the bitumen supply landscape in South Africa, both FFS and ourselves view this as the beginning of a long-term strategic partnership which will hopefully see this being the first of many cargos being supplied into these tanks in Cape Town. Plans are already in place for our next shipment, in May 2022, which we will be offering both 50/70 and 70/100 grades.

THE BEGINNING

The South African refineries landscape has changed with the closure of Astron refinery in Cape Town and Engen refinery in Durban. As a result, bitumen demand surpass the local production capabilities and imports are now required. RUBIS ASPHALT made a landmark beginning in South Africa at Durban when on 13th September 2021, the ‘VIVEKA’ berthed at Maydon Wharf, Durban. This RUBIS Bitumen delivery is also the first delivery of imported Bulk Bitumen into Durban port in almost a decade.

THE STORY

Following a nearly six-month period of extensive negotiations and engagements with customers and all other stakeholders, RUBIS delivered this first shipment of nearly 8900 Metric Tons of Bitumen comprising 3 different Grades (35/50, 50/70 and 70/100) into Durban and Cape Town. This is the largest shipment of bitumen ever imported in South Africa.

LOGISTICS & OPERATION

This shipment together with setting up a dedicated unloading facility and permanent bitumen storage facility has seen RUBIS ASPHALT establish their presence in this great land of explorers. After the successful discharge in Durban, the Viveka headed to Cape Town. In the late hours on Friday 24th September, the Viveka berthed in Cape Town and commenced discharge soon after. Most of the sales were done directly from the ship gantry, and we kept safety stock in Cape Town in our own bitu-containers to ensure supply reliability to our customers.

THE TEAM

In Durban & Cape Town, we were extremely fortunate for and thank Manga Tidiane of ERES SENEGAL, Brad Coucom of BRS Group and all RUBIS ASPHALT Team members for their excellent Service & Efforts to ensure smooth and efficient cargo discharge operations with the highest compliance to the RUBIS QHSE code.

The RUBIS ASPHALT team received excellent reviews from customers and service providers alike and are already planning the next shipment in November 2021.

“If there are dreams about a beautiful South Africa, there are also Roads that lead to their Goal……………” Nelson Mandela

On 11th December 2021 teams of Rubis Asphalt Middle East and Rubis Middle East Supply participated in Clean Up UAE campaign at Al Qudra Lakes in Dubai.

This event was held under the patronage of the UAE Ministry of Climate Change and Environment.

A total of 13,650 kg of waste material was collected and handed over to the municipality for further processing and disposing.

It was a good opportunity for our teams to take part in promoting sustainable development and community recycling in the UAE and to raise awareness on the importance of environment protection.

In a bid to sustain and even reinforce our positions in bitumen market in Nigeria, and with the perpetual quest to continue highly satisfying our customer requests in a tough competition market, RNL is soon going to add 20 of modern Bitumen Tankers to its existing fleet of already 100 customized trucks of the same type that deliver regular 60/70 hot bitumen and Polymer Modified Bitumen to construction sites across the whole country.

The increase became necessary because it will enable us to meet up with the high demand in the supply of Bitumen and Bituminous products at the expected quality standards and adequate temperature immediately ready for asphalt production by customers to any part of the country.

Those tankers of 45 MT product capacity each have been produced by FOTON in China on the basis of very detailed specifications imposed by RNL and have now been loaded into the ship which will bring them up to their final destination. Their expected time of dispatch is 5th of September 2021, and the transit time should be around 50 days.

For the time being, the factory has only equipped them with a classical external insulation but as soon as they arrive in Nigeria, a high-density internal insulation will be added as the last step before they can join operations. This last process owned by Ringardas and developed with a raw material which can only be obtained in Europe will be successfully carried out at our workshop in Gwagwalada by our specialized team.

The management of RNL is committed and ready to contribute their own quota to the development of road construction in Nigeria.

Rubis Asphalt Middle East is pleased to announce the creation of a new bitumen affiliate named Eres Gabon to pursue our expansion in Central Africa.

The company has been incorporated in April 2021 and will import, store and distribute bitumen to all road contractors in Gabon.

Our implantation has been triggered by a major road project called ‘Transgabonaise’, linking Libreville to Franceville with 780km road to be paved.

Our business model will be through ship to containers operations in partnership with Bollore Logistics, and we will be able to offer supply reliability and product quality to all our customers.

We have appointed Ms. Frederique Dumont to run our operations in Gabon as Deputy General Manager.

We have successfully performed our first ship delivery end of May through a good team work displayed by the bitumen division, as staff from Senegal, Cameroon, Togo, UAE and India were involved in this project.

We wish Eres Gabon and its team great success in this new venture!

Clean water is an essential resource for communities around the world. According to the United Nations Statistics, one in three people live without access to quality water, thereby causing unnecessary disease and death. However, huge strides have been made on a global scale towards providing access to clean drinking water, especially to the rural populace who are more confronted with the problem. It is on this account that Ringardas Nigeria Limited sees it as a necessity to provide clean water using a solar-powered borehole project for the people of Jogana Community in Kano State to enable them to have access to clean water to improve domestic hygiene.

The solar energy-driven borehole project donated to the Jogana community was completed and handed over to the local community stakeholders on the 19th of January 2024. The Management of Ringardas Nigeria was duly represented by the Head of Corporate Affairs department, Mrs. Nana Shaibu accompanied by the Kano Terminal Manager, Mr. Francis Nwachukwu, and some other staff of the company. The event witnessed a large turnout of the people of the community with all the revered traditional rulers in attendance.

The Highest Chief of the community who was appointed to speak for the community offered prayers and appreciation for the company and presented that safe and readily available water is important for public health, whether it is used for drinking, domestic use, food production, or other purposes. He went further to declare that the water project will undoubtedly improve the livelihood of the people of the community and assured the team of RNL present that the community will continue to appreciate the good gesture of the company. Other community representatives who were also present could not hide their utmost joy as they appreciated the fact that the use of solar-based technology would reduce the burden of epileptic power supply from the utility grid and the elimination of operation and maintenance cost of fuel required for the borehole pumping system.

Millions of people around the world do not have access to basic clean water. This means they must rely on sources like wells, rivers, or lakes which are prone to contamination, or walk a far distance to collect clean water.

It is on this note that RNL decided to come up with this project as part of our CSR to the host community where we operate, to provide them with clean water. In line with the group’s effort targeted at reducing zero emissions and promoting clean energy, Ringardas took a step to install a solar borehole system at Bundu Ama community, which was funded by Rubis group.

This system is sustainable and uses renewable energy as it generates electricity from solar panels to drive the borehole pump. Compared to a classic bore-hole system, where the electricity is generated through a generator, the solar variant does not produce harmful pollutants which keeps the air and soil clean.

On the 2nd of August 2023, our Terminal Manager in Port Harcourt, Adegboye Akinkunmi, accompanied by other colleagues represented Ringardas at the official hand-over of the solar borehole to the Bunda Ama community, represented by the Community Chairman, the Community Laison Officer (CLO), and some Community Chiefs. The Community Chairman Mr. Otonye Boma in his speech, thanked the management of Ringardas Nigeria Limited and appreciated them for their kind gesture in supporting their community, and they look forward to other projects in the future.

ERES Togo, with funding support from Rubis Asphalt Middle East, launched on Friday, June 3, the mangrove restoration project on Ghin Island in Aného, a city in eastern Togo.

This island at the confluence of Lake Togo and the Gulf of Guinea suffers from erosion of strong currents related to the inflow and outflow of water in the lake during the tides. The objective is aim to plant 5000 mangrove trees around the island and 4000 trees of other species (Khaya, Cola gigantea, Mitragina inermis, Ebony, Gmelina, Campeche logwood, Dialium, Pterocarpus erinaceus) in the interior of the island, on a total area of 32ha.

We chose this type of reforestation for the strong impact it will have both on local populations and on CO2 storage. Mangroves have a CO2 storage capacity up to 8 times higher than traditional terrestrial forests and mangroves require very little maintenance as they are partially in the water. Mangroves are also part of a complex ecosystem, combining aquatic fauna, birds and rodents. The roots provide a great refuge and spawning ground for fish and shellfish. The local economic activity will benefit from this improvement of the halieutic resource (shrimps and fish) in the lake and the mangroves will reinforce the tourist attractiveness of the city.

Following by the maintenance and awareness program for local populations, especially children, on the preservation of the environment and the importance of the mangrove, this sustainable project is fully in line with objective 1 (reduce the environmental footprint) and 3 (contribute to a more virtuous society) of the Rubis group’s CSR approach.

It was little surprise that Ringardas received and responded positively to the request of the Nigeria Coaches Association Kwali Area Council (in March 2021), for sponsorship of a football competition which later commenced in the local community on 8th June. Indeed,

Ringardas found it essential and pleased to sponsor the competition by providing the following items: footballs, sets of jerseys for 8 different teams, goal post nets, trophies, medals, certificates, and t-shirts/face caps for the tournament. As it is our culture to give back to the communities where we operate. We believe this will assist the Coaches Association seeking to use the competition to develop youth talent in sport; arrest youth restiveness; and foster peaceful coexistence among members of the Area Council.

The closing ceremony of the football competition which took place on 8th, July was attended by our Corporate Affairs Manager Mrs. Nana Shaibu, who represented the Managing Director of RNL, who could not attend the event due to his busy schedule. She was invited to kick off the ball to commence the final game. And the winner of the competition was Kolo Babes. RNL’s Managing Director Mr. Philippe Goron and the Corporate Affairs Manager Mrs. Shaibu were honored with awards of recognition by the Kwali Football Council/Federal Capital Territory (FCT) Football Association (FA), following an appreciation letter sent to the company. The organizers stated that the awards represent tokens of the community’s appreciation for the support offered by Ringardas Nigeria Limited.

Ringardas is committed in its policy and practice to maintaining and expanding its outreach programs in local communities across Nigeria where we operate.

The financing by ERES Togo (Bitumen subsidiary of Rubis Energie) of the reforestation of 2 hectares in the town of Kozah 3 near Kara, is part of the national reforestation plan and aims to improve the environment of the inhabitants by limiting soil erosion and offering a future source of income with the exploitation of fruits and wood.

500 trees (coconut trees, soursop trees, caïlcedrats) have been planted and will be monitored by the NGO Envir-Afrique on land belonging to the Town Hall.

On July 17, the Management visited the site in the presence of the Mayor of the town, Hon. PISSIYOU Sami Essokudjowu and his deputies.

Access to water, which is recognized as a basic need, is very difficult in some localities.

In Senegal, the village of Ndour-Ndour located 267 km from the capital was facing a real water supply problem.

Indeed, the inhabitants had to make an obstacle course every day in order to have access to this vital resource, which considerably slowed down the development of this part of the country.

Faced with this problem, the NDIMBEUL association in partnership with ERES Senegal (bitumen subsidiary of the Rubis Energie group) has set itself the objective of improving the living conditions of these inhabitants.

A sustainable solution has been put in place to facilitate access to water. The design of a mini borehole 10 meters deep accompanied by a solar submersible pump connected to a manual fountain. The storage of water is done in a water tower and the distribution by gravity to the fountains.

As seen in this photo, at the inauguration of the well it was celebrations. The population of Ndour-Ndour welcomed this achievement with immense joy and unfailing gratitude to the NDIMBEUL association and ERES Senegal who have since the end of 2020 greatly improved their daily living conditions.

As part of Ringardas Nigeria Limited’s Corporate Social Responsibilities which is showing CARE to the host communities where we have our presence, RNL has awarded scholarship to 10 Undergraduates in Sapele Okpe Community. These students are currently studying at both Government and Private universities within Nigeria. We aim at supporting the awardees throughout the period of their studies to enable them achieve their career aspirations with ease and contribute positively to the society.

#AscaBitumen #RingardasNigeria

#Education #SupportingCommunities

#PavingWaysIntoTheFuture

We invite you to visit us at https://ascanigeria.com

As we continue in the fight against the spread of COVID-19 Pandemic, Ringardas Nigeria Limited has boosted the response of some hospitals in the country. This was accomplished via donations of reusable nose masks to medical personnel’s in some prominent hospitals and local communities. This gesture was borne out of CARE which is also part of our core values for the communities where the company operates. It is the desire of the management of RNL to see that there is continuity in business and also find a means of coping with the NEW NORMAL since no one can tell exactly when the pandemic will be over. We hope to continue to do more in our own little way because we believe that we are stronger together when we take collective action to help each other stay safe. # Stay safe and stay healthy.